NOF and solder mounting materials

Many alloys are under consideration as replacements for lead-based solder.working on tin-alloys, which have a melting point near that of lead-based solder and provide the opportunity to use NOF’s expertise in blocked carboxylic acid technology. Research is focusing on ways to solve the problem of metal deterioration caused by a chemical reaction with the carboxylic acid contained in the flux.

Solder particle

What is solder?

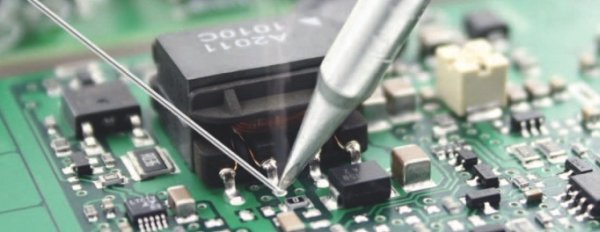

Solder is an age-old technique used to connect two types of metals. In the electronics industry, solder is used to attach electronic components to copper circuit lines on printed circuit boards.

What is solder

All about flux

Flux is a compound that includes carboxylic acid, often from rosin made from pine sap. Flux performs the following functions that are essential to linking two surfaces using solder.

Rosin

Using rosin or other chemical compounds containing carboxylic acid, flux plays a vital role in soldering as shown below.

Surface tension of solder coated by molten flux

Functions of flux

(1) Removes the oxide film from metal surfaces 2RCOOH + Cu2O -> 2RCOOCu + H2O

(2) Prevents oxidation by coating the solder

(3) Lowers surface tension

What is solder paste?

Solder paste is made by mixing a fine solder powder with liquid flux to produce a compound with a paste-like consistency. This paste is printed on the copper circuit pattern where components are to be mounted. Once components are in place, the board is heated to melt the metal in the solder and hold the components to the board.

Improvements in solder composition

An alloy of tin and lead was commonly used for many years but is no longer acceptable due to environmental issues. Companies are being required to switch to solder alloys that do not incorporate lead.

Harmfull things

Due to problems associated with reliability of the metal following

attachment, and to other issues, interest is currently focused on tin-silver compounds that have a melting point about 40°C to 50°C higher than lead-based solder. As a result, improvements are needed to make components that are resistant to higher temperatures and to enhance the performance of soldering ovens.

In addition, some companies have started studying tin-zinc compounds because they can be used with existing soldering ovens.

Melting points of solder alloys

PCB soldering

PCB soldering

Packing

Packing