Feature:

1. Favorable fatigue resistance and outstanding performance

2. Ultra high electrical conductivity

3. Mid-temperature soldering, characterized by nice softness and wonderful wetting property.

4. Benefit from activated rosin core flux.

5. Ultra strong oxygen resistance. Due to the anti-oxygen material in the solder wire,Sn63Pb37 no clean solder wire can give strong resistance to oxygen.

Low Dross Characteristics:giving cost effective use of the solder alloy.

Low Dross Characteristics:reducing the amount of dross in the wave pot leading to lower downturn and reducing the chance of oxide entrapped in joints.

Manufactured to Alpha’s high standards: giving a product that can be relied on to give good consistent soldering performance.

Chemical content:

|

Impurity content % |

| Sn |

Pb |

Sb |

Ag |

Cu |

Fe |

Zn |

Bi |

Al |

As |

Ni |

Cd |

| 60±2 |

40+/2 |

≤0.10% |

≤0.02% |

0.1% |

≤0.02% |

≤0.001% |

≤0.10% |

≤0.001% |

≤0.03% |

≤0.01% |

<0.01% |

| 59.3 |

bal |

0.032 |

0.0002 |

0.0057 |

0.002 |

0.0015 |

0.006 |

0.0024 |

0.0021 |

0.0032 |

0.0001 |

Maximum Allowed Impurities

solder Bar Solder meets the requirements of current industry standards for allowable impurity requirements. Elements are considered impurities if they are not listed as components in the composition of the alloy.

Storage and Shelf Life:

Sn60Pb40 bar solder has no limited shelf life when handled properly.rage must be in a dry,non-corrosive environment. The solder surface may lose its shine and appear a dull shade of gray. This is a surface phenomenon and is not

detrimental to product functionality.

Tin-lead solder bar size as follow:

Alloy composition

Sn/Pb |

Specific gravity |

Liquid temperature |

Temperature |

Application |

|

|

|

|

|

| 63/37 |

8.39 |

183 |

220~240 |

Computers, precision instruments, meters, TV, |

| 60/40 |

8.65 |

190 |

230~250 |

micro technology, coating metals |

| 55/45 |

8.75 |

200 |

240~260 |

Calculators, tape recorders, telephones, quartz and |

| 50/50 |

8.85 |

216 |

255~275 |

other common electronic and electrical products |

| 45/55 |

8.97 |

227 |

270~290 |

| 40/60 |

9.30 |

238 |

295~310 |

General circuit boards, toys, lamps, crafts, water tanks, plumbing solder |

| 30/70 |

9.70 |

260 |

310~325 |

| 20/80 |

10.05 |

275 |

325~335 |

General circuit boards, toys, lamps, crafts, water tanks, plumbing solder |

Sn60Pb40 Solder bar for wave-soldering;

Solder bar for dip soldering;

Solder bar for auto water tank;

Solder bar for industry electroplating.

Health & Safety:

This product, during handling or use, may be hazardous to health or the environment. Read the Material

Safety Data Sheet and warning label before using this product.

Packing

Size:32×1.8×1.2×2.0 cm; weight 0.78-0.83kg/pc

Packing:10kg/crton; 30kg/export carton

Dimension of carton:36x26x18cm

Shipping:

We guarantee to ship out within 48 hours after payment confirmation (except Holiday).Once the payment is received please allow 48 hours for dispatch of the order.

| Country |

Processing Time |

Arrive time |

| United States |

2 days |

7-15 days |

| United Kingdom |

2 days |

7-15 days |

| Australia |

2 days |

8-18 days |

| Canada |

2 days |

8-18 days |

| Netherlands |

2 days |

8-18 days |

| Spain |

2 days |

15-25 days |

| Italy |

2 days |

15-25 days |

| Germany |

2 days |

15-25 days |

| Other Countries |

2 days |

2-3 weeks |

Contact:

All emails will be answered within 24 hours.

Please leave a message in the Trade Manager.

If you do not receive our reply, please kindly re-sent your email and we will reply you as soon as possible . If you email us and dont hear a reply, please email again through the Alibaba system as sometimes our mail servers have errors

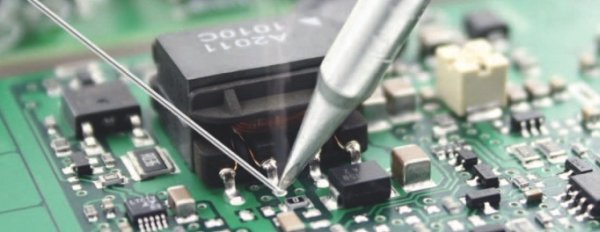

PCB soldering

PCB soldering

Packing

Packing