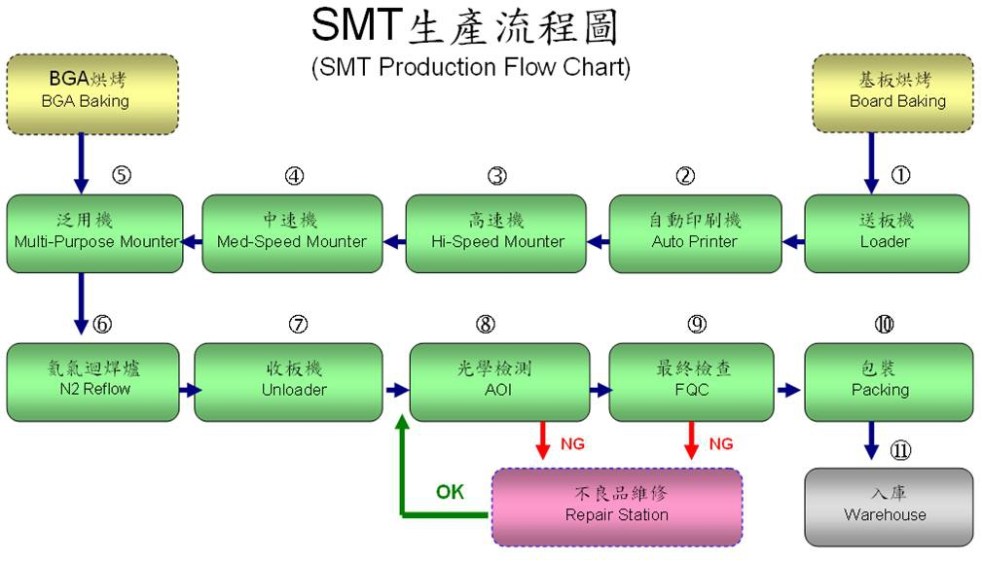

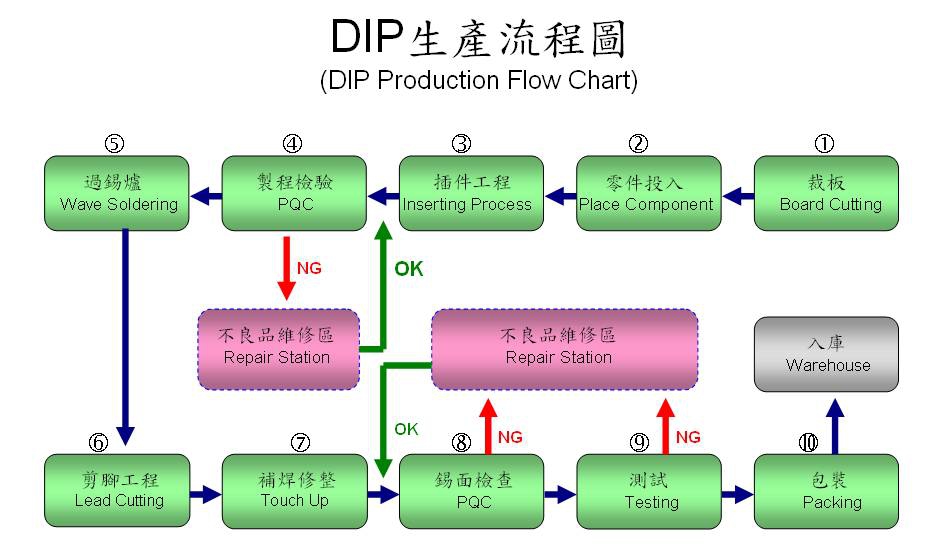

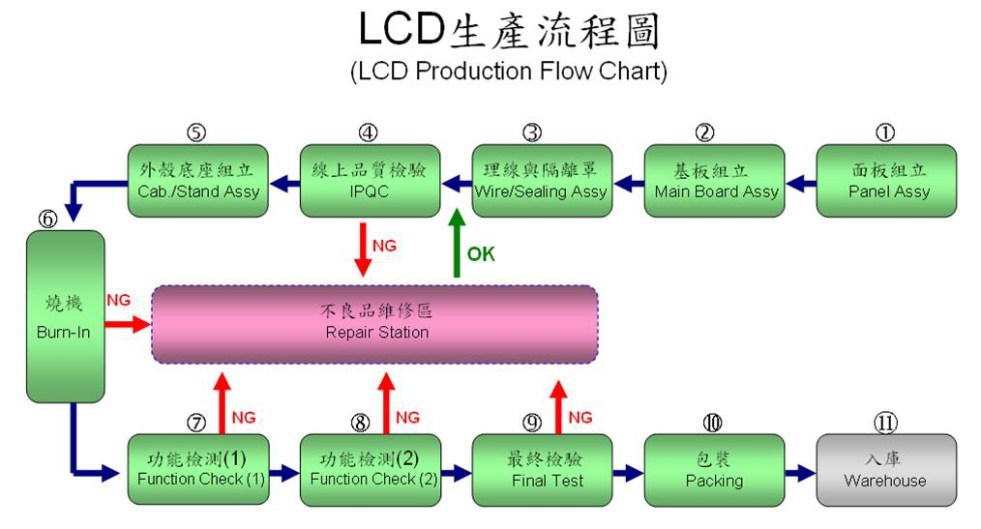

As we all know the Production Flow Chart is very important for the factory. So we make the three SMT, DIP ,LCD chart for customer reference .If you have any question on SMT , DIP or LCD ,Please feel free contact us .

SMT flow chart need Borad baking ,Loader,Auto printer,Hi-speed mounter,Med-speed mounter,Multi-purpose mounter,N2 reflow ,Unloader,AOI,FQC,Packing, Warehouse.

DIP flow char include Board cutting,Place component,Inserting process,PQC,Wave soldering,Lead cutting,Touch up,PQC,Testing,Packing.

LCD flow chart include Panel assy,Main board assy ,Wire/sealing assy , IPQC ,Cab/stand assy,Bum-in,Function check(1),Function check(2),Final test, Packing, Warehouse

Very nice blog and infomartion your are sharing with us! lead free wave solder machine

赞赞